Comprehensive Guide to Stainless Steel Honeycomb Sheets by Top Metal Fabricators

In the realm of advanced industrial materials and innovative design solutions, stainless steel honeycomb sheets stand out as a remarkable choice for architects, engineers, and manufacturing professionals alike. These sophisticated panels offer an unparalleled combination of strength, durability, aesthetic appeal, and versatility, making them a preferred material in numerous sectors including construction, aerospace, automotive, and decorative architecture.

The Evolution and Significance of Metal Fabrication in Modern Industry

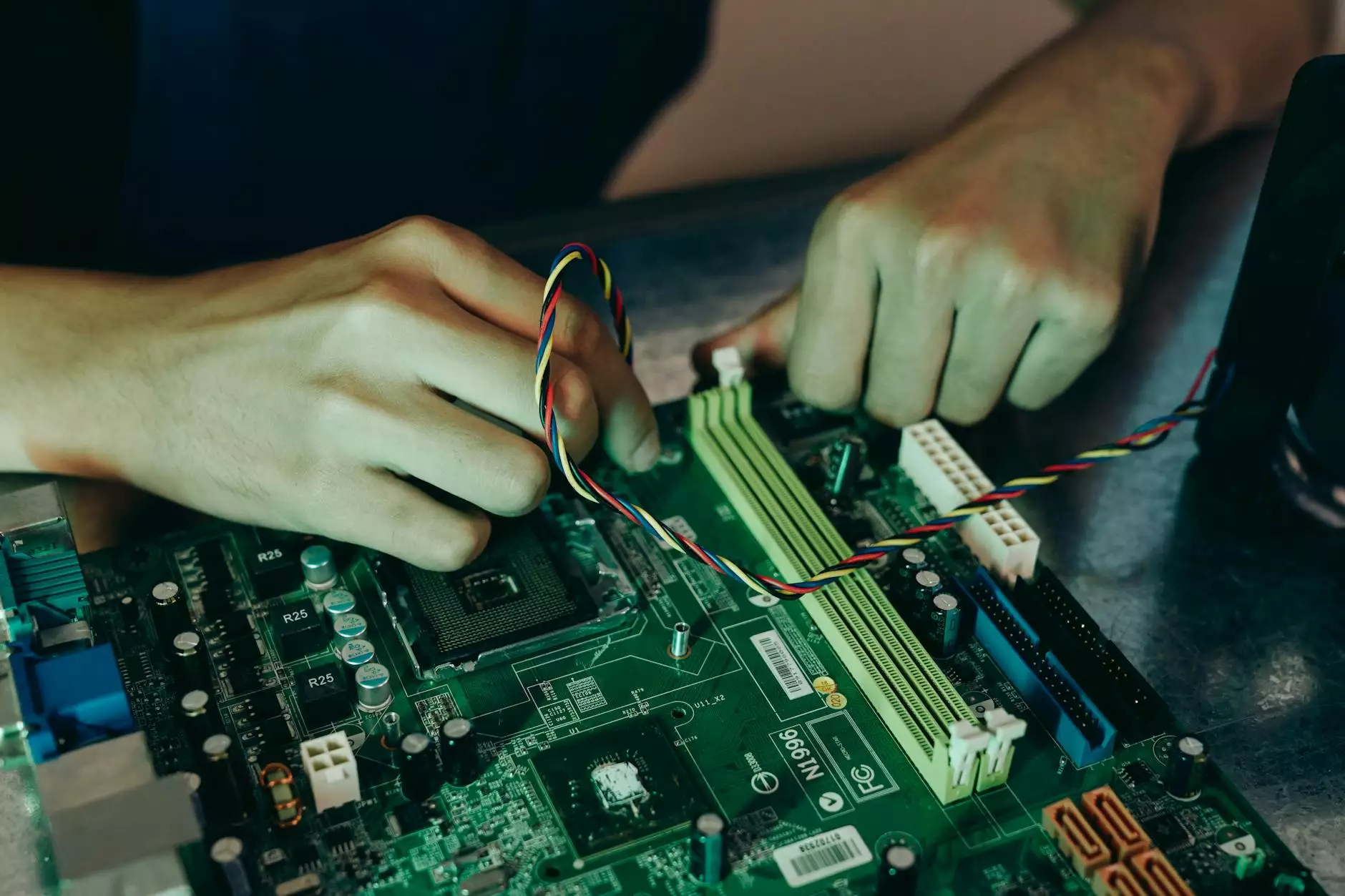

Metal fabrication has been a cornerstone of industrial progress for centuries, evolving from simple forging techniques to highly precise processes that enable the creation of complex, high-performance components. Metal fabricators such as Goldeco Steel specialize in transforming raw metal materials into custom-designed products that meet the highest standards of quality, safety, and functionality. Among the array of materials they work with, stainless steel holds a prominent position due to its exceptional properties, especially when fashioned into innovative forms like honeycomb sheets.

Understanding Stainless Steel Honeycomb Sheets: Composition, Structure, and Manufacturing

The stainless steel honeycomb sheet is a structured panel composed of multiple layers of stainless steel sheets assembled in a honeycomb pattern. This pattern resembles the natural design found in beehives—featuring hexagonal cells that offer extraordinary strength-to-weight ratios and support for various applications.

Material Composition and Types

Stainless steel honeycomb sheets are generally fabricated using premium-grade stainless steel varieties such as 304, 316, and 321. Each type offers unique benefits:

- 304 stainless steel: Known for excellent corrosion resistance and good mechanical properties, ideal for general-purpose applications.

- 316 stainless steel: Higher corrosion resistance, especially in aggressive environments like marine settings, making it suitable for outdoor and coastal projects.

- 321 stainless steel: Includes titanium for enhanced high-temperature performance and stability in heat-exposed environments.

Manufacturing Process of Honeycomb Sheets

The process involves several meticulous steps to ensure high-quality end products:

- Metal Sheet Preparation: Raw stainless steel sheets are cut to precise dimensions, often through CNC machining or shear cutting.

- Forming the Honeycomb Core: The sheets are mechanically punched and folded into hexagonal cells that form the honeycomb structure.

- Assembly: The honeycomb core is then sandwiched between smooth stainless steel panels using welding, riveting, or adhesive bonding techniques.

- Finishing: The finished panels undergo surface treatments such as polishing, passivation, or coating to enhance corrosion resistance and aesthetic appeal.

Advantages of Using Stainless Steel Honeycomb Sheets in Modern Applications

The integration of stainless steel honeycomb sheets into design and engineering projects offers numerous benefits, making them a superior choice over traditional flat panels or other composite materials.

Exceptional Strength and Structural Integrity

The honeycomb pattern inherently provides high mechanical strength while remaining lightweight. This characteristic allows for the construction of large panels that bear substantial loads without adding excess weight—crucial for applications where weight efficiency is vital.

Superior Corrosion and Weather Resistance

Given the composition of stainless steel, these panels withstand harsh environmental conditions, including exposure to moisture, chemicals, and temperature fluctuations. This makes them ideal for outdoor architecture, facade cladding, and marine environments.

Enhanced Aesthetic and Design Flexibility

Stainless steel honeycomb sheets create striking visual effects when finished properly. They can be polished to mirror-like finishes, brushed for matte effects, or custom textured, offering architects and designers a palette of options to craft unique facades, ceilings, and decorative features.

Thermal and Acoustic Insulation Properties

The honeycomb structure naturally provides excellent insulation characteristics, making these sheets suitable for building envelopes and interior partitions where thermal efficiency and sound absorption are priorities.

Easy Maintenance and Long-Term Durability

With proper surface treatment, stainless steel honeycomb sheets are resistant to staining, scratching, and degradation, ensuring a long lifespan with minimal maintenance requirements.

Industry Applications of Stainless Steel Honeycomb Sheets

The versatility of these panels allows their application across a wide spectrum of industries, some of which include:

Architectural and Exterior Cladding

Modern buildings increasingly leverage stainless steel honeycomb panels for elegant facades, offering a sleek, reflective surface that enhances curb appeal while providing weather resistance.

Interior Design and Decorative Elements

Interior designers utilize these sheets for feature walls, ceiling panels, and custom furniture, adding a contemporary industrial aesthetic that combines functionality with visual appeal.

Soundproofing and Acoustic Panels

The inherent acoustic properties of honeycomb structures make them invaluable in theaters, conference halls, and urban settings requiring noise reduction.

Industrial Equipment and Filtration

Due to their strength and corrosion resistance, stainless steel honeycomb sheets serve as filters, separators, and components in chemical processing, HVAC systems, and food production.

Automotive and Aerospace Components

High-performance industries adopt honeycomb panels for lightweight interior panels, heat shields, and structural applications where durability and weight savings are essential.

Why Choose Goldeco Steel for Your Stainless Steel Honeycomb Sheet Needs?

As a reputable metal fabricator, Goldeco Steel specializes in producing premium-quality stainless steel honeycomb sheets tailored to client specifications. Here are some reasons why industry leaders and project managers trust Goldeco Steel:

- Expertise & Experience: Decades of specializing in advanced metal fabrications ensure precise manufacturing and innovative solutions.

- Customization Options: Wide range of thicknesses, finishes, and sizes to perfectly match project requirements.

- Quality & Certification: Rigorous quality controls, compliance with international standards, and certifications guarantee durability and safety.

- Advanced Technology: State-of-the-art CNC machines, laser cutting, and welding equipment facilitate complex designs and high precision.

- Customer-Centric Service: Dedicated support from consultation through installation ensures seamless project completion.

Considerations for Selecting the Right Stainless Steel Honeycomb Sheet

Choosing the optimal honeycomb sheet requires understanding specific project needs. Key factors include:

- Application Environment: Indoor or outdoor, exposure to chemicals, temperature ranges.

- Load-Bearing Requirements: Structural support versus aesthetic purposes.

- Finish and Appearance: Polished, brushed, or customized textures.

- Thickness and Size: Suitable for adhesion, installation, and compatibility with existing structures.

- Cost and Budget Constraints: Balancing quality with affordability for maximum ROI.

Future Trends and Innovations in Honeycomb Metal Fabrication

The industry continues to evolve with technological advancements and design innovations. Some emerging trends include:

- Enhanced Surface Treatments: Self-cleaning coatings and anti-corrosion finishes that prolong lifespan and reduce maintenance.

- Hybrid Materials: Combining stainless steel with other composites for tailored properties such as increased thermal insulation or fire resistance.

- Eco-Friendly Manufacturing: Adoption of sustainable practices and recyclable materials to minimize environmental impact.

- Modular and Prefabricated Panels: Simplified installation processes and scalable solutions for large-scale projects.

Conclusion: Elevate Your Projects with Premium Stainless Steel Honeycomb Sheets

Integrating stainless steel honeycomb sheets produced by skilled metal fabricators like Goldeco Steel can significantly enhance the performance, aesthetics, and longevity of your architectural and industrial projects. These panels exemplify durability combined with cutting-edge design flexibility, positioning your developments at the forefront of innovation.

Whether you are designing a cutting-edge commercial building, a resilient industrial facility, or an elegant interior space, choosing the right honeycomb stainless steel panels ensures superior quality and unwavering performance. With advancements in manufacturing techniques and a growing emphasis on sustainable construction, these structures are set to shape the future of modern architecture and engineering.

Investing in high-quality stainless steel honeycomb sheets from a trusted fabricator like Goldeco Steel provides peace of mind, unmatched durability, and the aesthetic sophistication that today’s discerning clients demand. Embrace the strength, versatility, and timeless appeal of stainless steel honeycomb panels and set new standards for your projects today.